Search By Parameters

Choose us For

Reliability

Our customers can trust our products for their most demanding applications.

On Time Delivery

Get your orders delivered on time every time with us.start trusting us for timely deliveries.

Cost effective

Our products are designed to be effective and reasonably priced, helping you stretch every dollar.

Best Service

We create meaningful relationships through exceptional service. By engaging with our customers

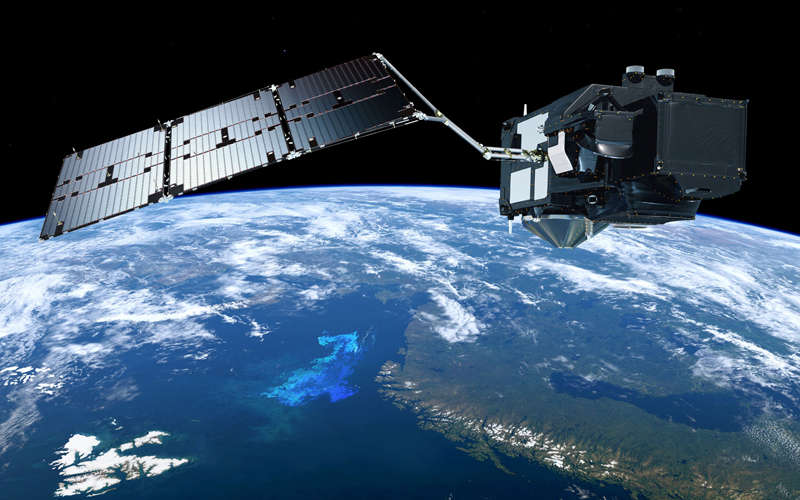

Our Sectors

Industrial

Telecom

Defence